Diamond Bite™ features

Continuous Blades

The Continuous Rim Diamond Blade is ideal for clean cutting applications including tile and masonry materials. A high concentration of premium industrial diamonds bonded in a complex diamond matrix yields a blade that cuts cooler — quicker, cleaner and up to 3x longer lasting than standard diamond blades. Cut wet or dry for increased versatility.

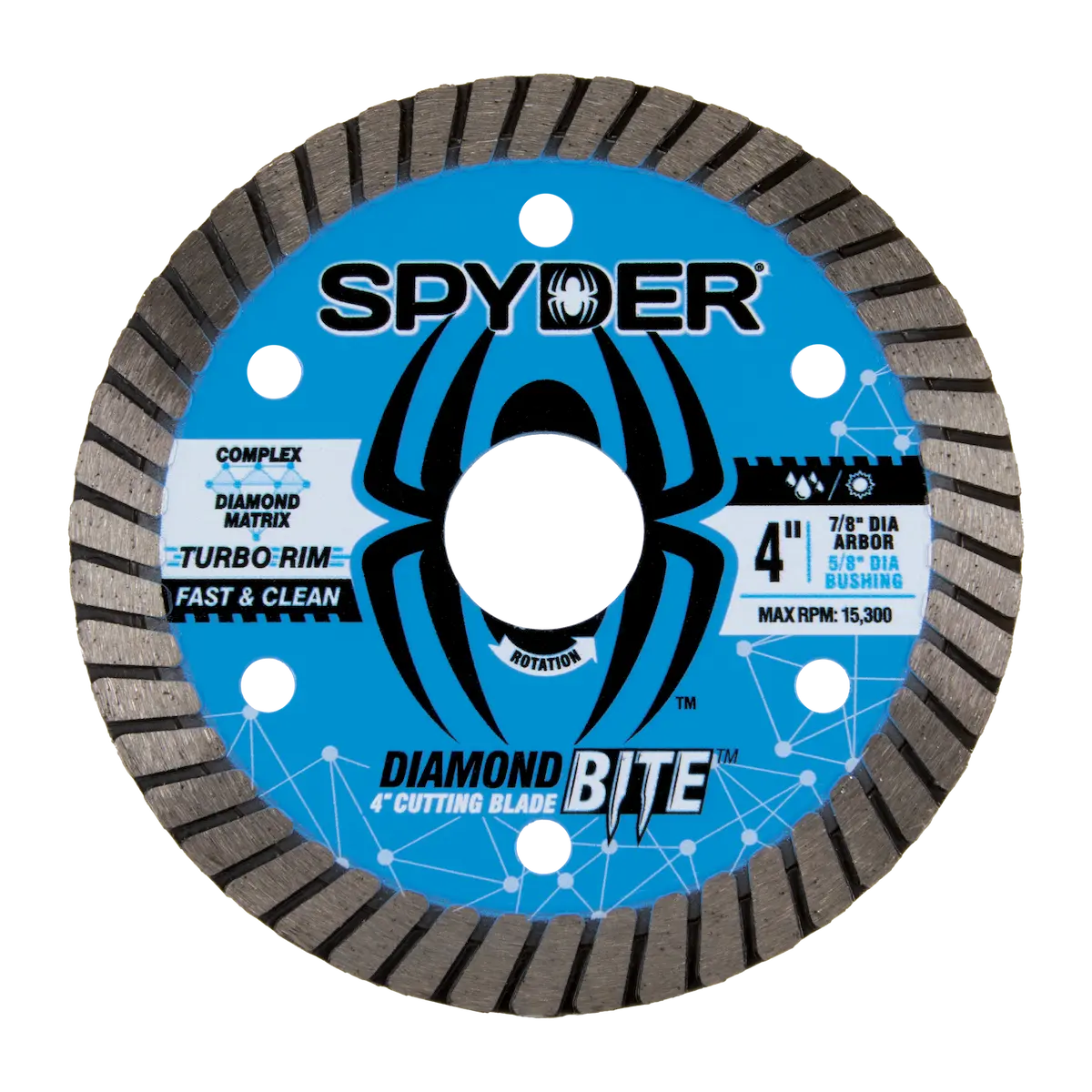

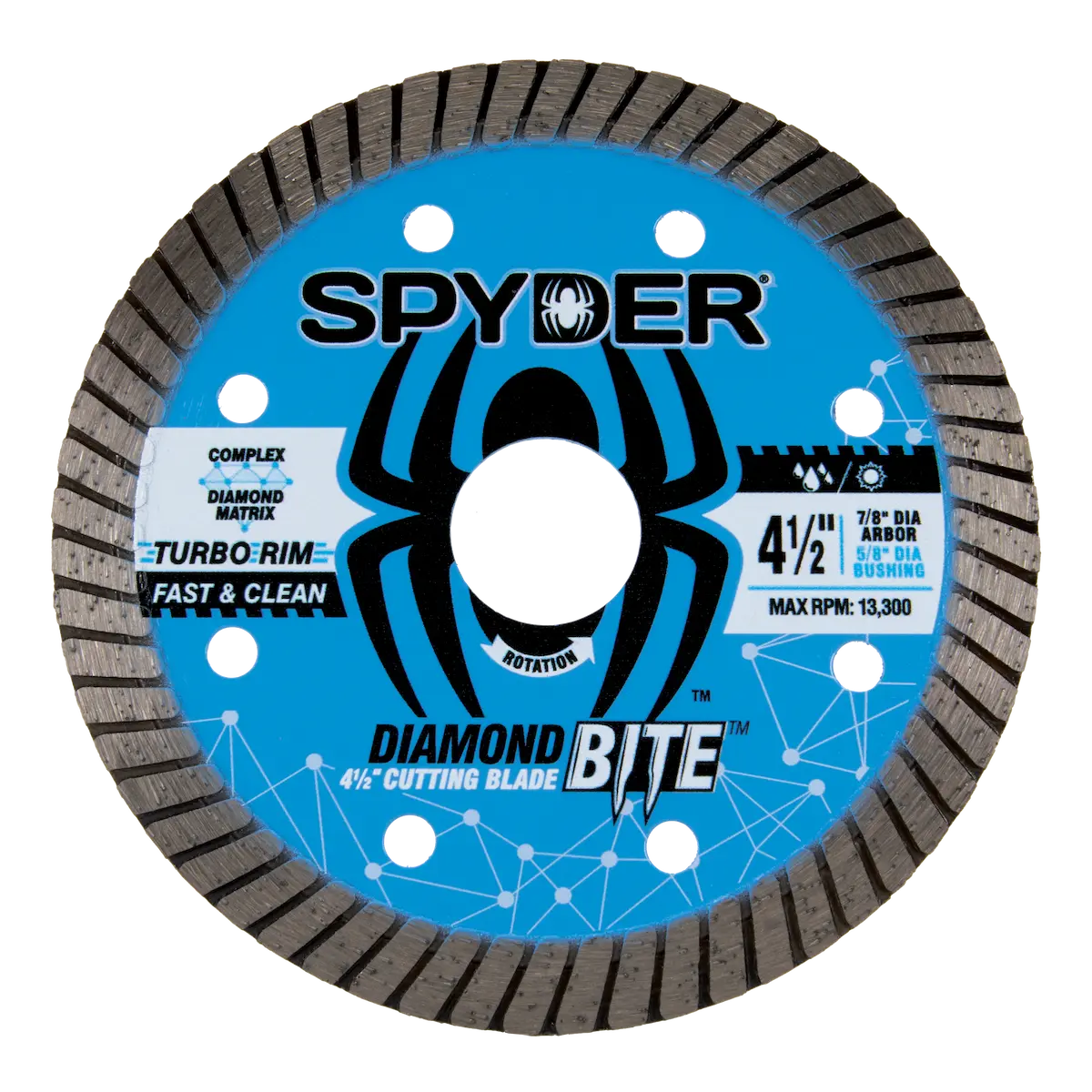

Continuous Turbo Blades

The Continuous Turbo Rim Diamond Blade is ideal for fast and clean cutting applications including masonry and concrete materials. A high concentration of premium industrial diamonds bonded in a complex diamond matrix yields a blade that cuts cooler — quicker, cleaner, and up to 50% longer lasting than standard diamond blades. Cut wet or dry for increased versatility.

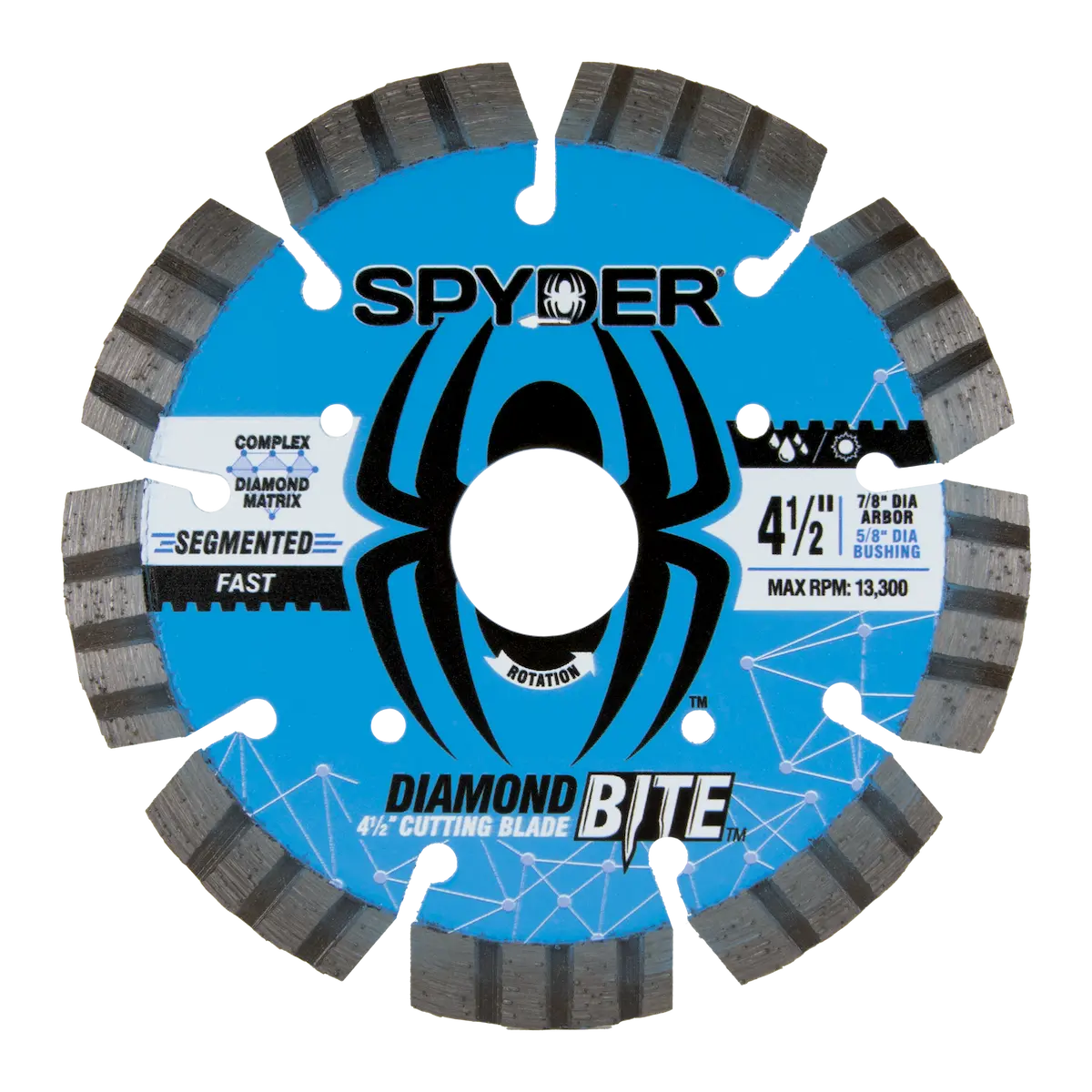

Segmented Blades

The Segmented Turbo Rim Diamond Blade is ideal for fast and clean cutting applications including masonry and concrete materials. A high concentration of premium industrial diamonds bonded in a complex diamond matrix yields a blade that cuts cooler — quicker, cleaner and up to 5 times longer lasting than standard diamond blades. Cut wet or dry for increased versatility.

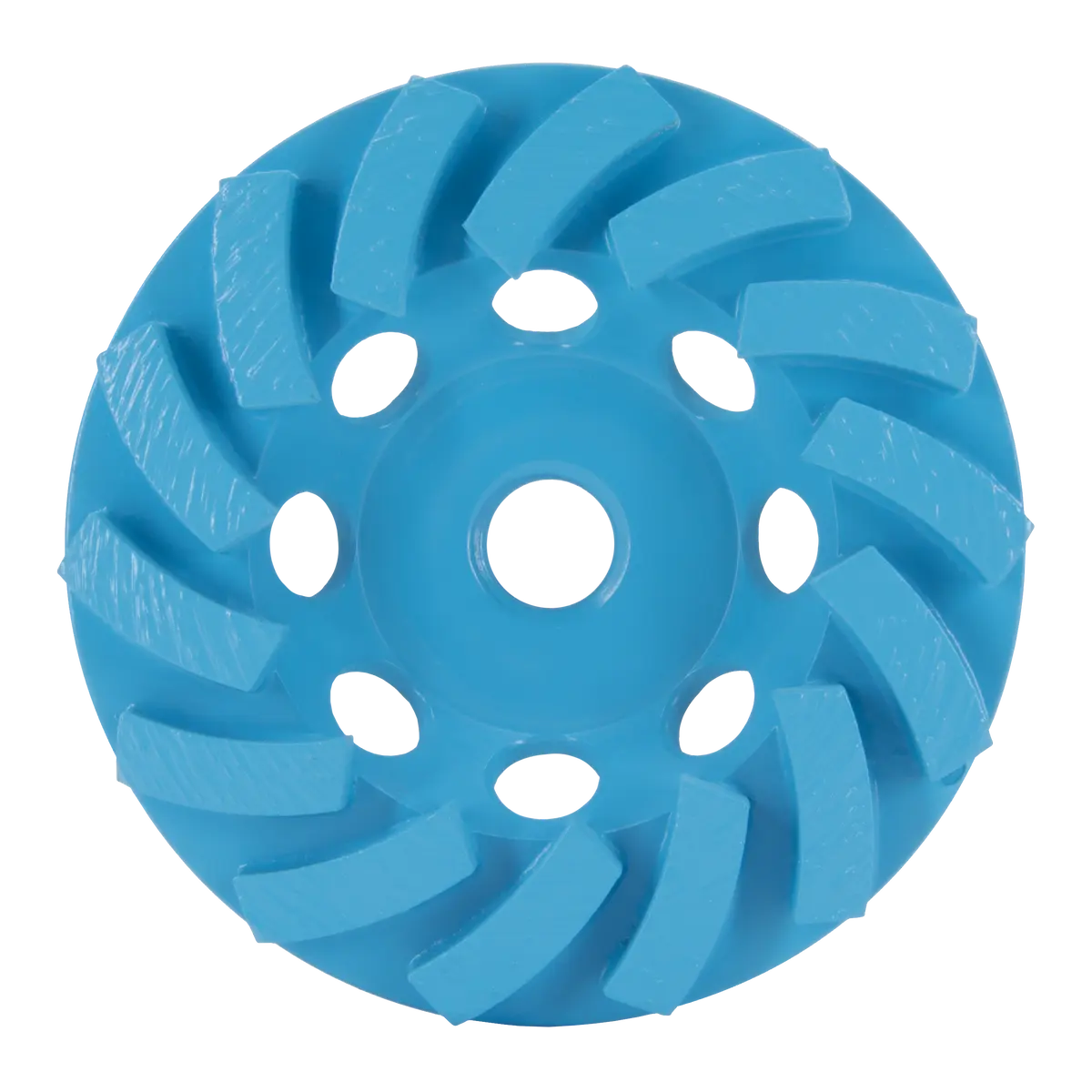

Cup Wheel

- Ideal for porcelain tile, ceramic tile, masonry, block and brick

- Premium-quality industrial diamonds provide quick and clean cuts

- Complex diamond matrix bond retains diamond abrasive for extended cutting life

- Use wet or dry for increased versatility

- Balanced blades provide vibration-free cuts for optimum cut cleanliness

Warning

To reduce the risk of injury, read the instruction manual and follow the safety regulations of the power tool you will be using with your Spyder accessory. Use personal protective equipment. Always wear eye, face, ear, and respiratory protection. Use the appropriate mask or respirator in dusty work conditions. Protective equipment such as a body apron and non-skid safety shoes should be used in appropriate conditions to reduce the risk of personal injury. WARNING: Operating the tool without wearing proper protection may result in serious injury. Exposure to noise can cause hearing loss. Do not use near flammable materials or gases! Fire or explosion may result due to ignition from the hot surface. To reduce the risk of explosion, electric shock, and property damage, always check the work area for hidden gas pipes, electrical wires, and water pipes when making blind cuts. Before each use, check that the blade/cup is free from flatness, fatigue cracks, segment damage and damage to the blade core and center arbor hole. Discard blade/cup if dropped, cracked, or chipped, or if any other damage is noticed or suspected as this can cause excessive friction, blade binding, kickback, create dangerous flying debris and/or create other unsafe situations that may cause injury. Always use blades/cup of the correct size with the correct arbor hole shape and size for your power tool. Blades/cups that do not match the mounting hardware of the saw will run eccentrically, causing loss of control, increasing the risk of personal injury. Make sure the speed marked on the blade is at least as high as the no-load RPM marked on the power tool. To assure proper rotation direction of the blade, the arrow direction on the blade must correspond with the arrow direction on the saw. Mount blade/cup with the flange and nut intended for the power tool. To reduce the risk of injury, never operate the power tool without correct safety guards in place; guard foot should be adjusted for maximum operator protection and stability. Only use blade/cup for cutting or grinding materials that are listed on the package. After installing blade and before cutting application, run blade in power tool for one minute, facing away from any persons in the vicinity. Start cutting with a light forward pressure. Do not jam, twist or pinch blade in the workpiece, or apply excessive side pressure to the blade – kickback may occur if blade is jammed. Always let the blade/cup come to a complete stop before setting the power tool down. Do not touch blade/cup immediately after use as it may still be hot and burn you. Never cut through into the dirt as it will cause excessive wear on the blade.