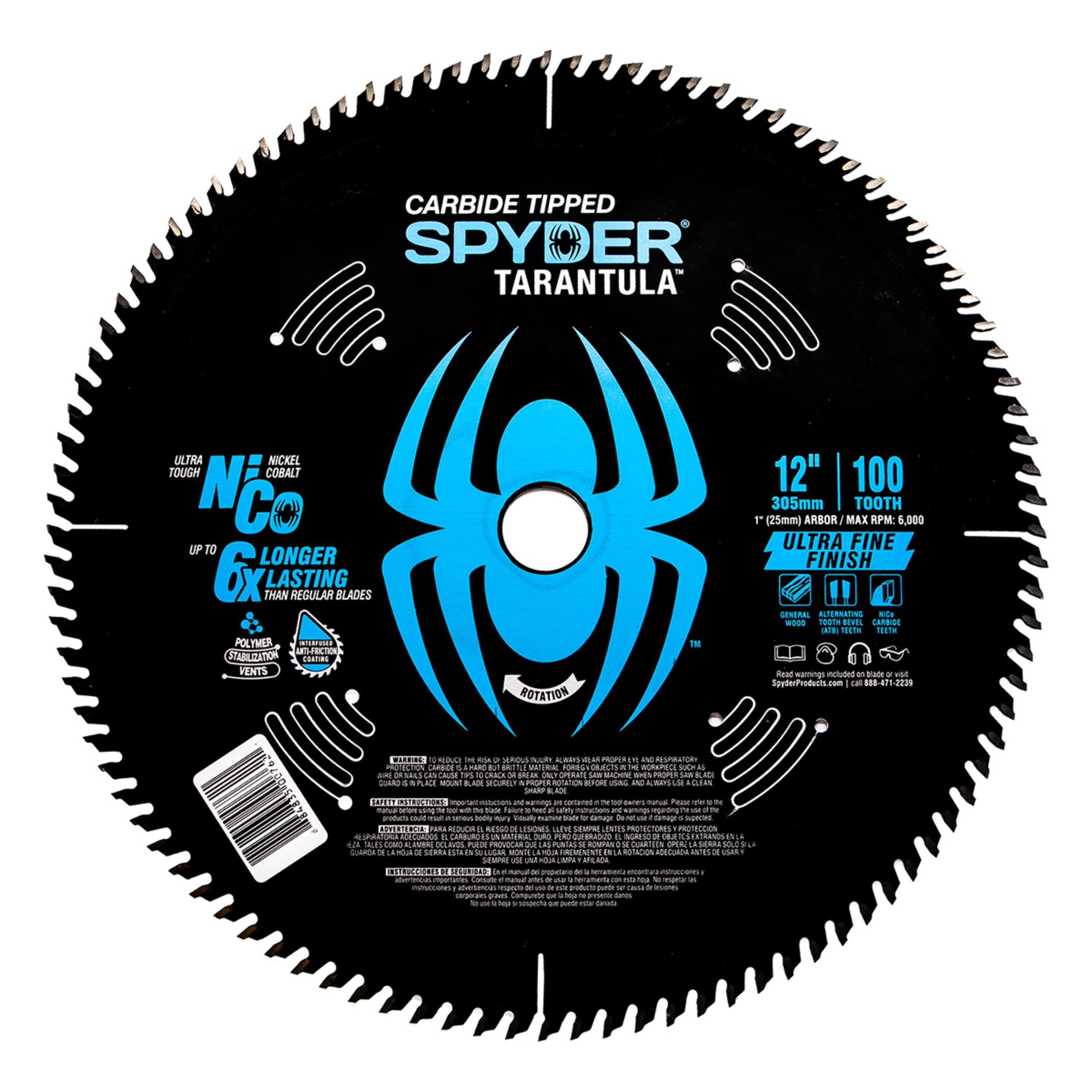

12" 100-Tooth Ultra Fine Finish Saw Blade for Wood

SKU: 13027

- Up to 6x longer lasting than regular blades

- Ultra tough NiCo (nickel cobalt) cutting teeth make the cleanest cuts

- Smooth running and quick cutting — Carbide-tipped blades provide durable cutting over the life of the blade

Product Details